FORMULA SAE

OREGON STATE UNIVERSITY

Senior Capstone Project GFR15

As part of Oregon State University’s Formula SAE team, I developed and piloted a new method to certify composite monocoque chassis designs. This approach utilized simplified composite sandwich panel tests paired with detailed finite element analysis (FEA), enabling efficient certification within the constraints of Formula SAE rules.

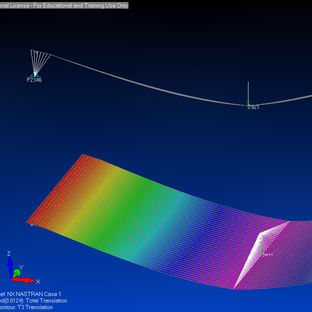

I began by conducting physical tests on composite panels, using techniques like tensile, bending, and point deflection tests to validate the mechanical properties of the materials. Simultaneously, I developed a detailed FEA model of the chassis using Siemens FEMAP, allowing us to predict structural performance under various load cases. This workflow significantly reduced reliance on physical testing, saving time and materials while ensuring compliance with strict design regulations.

To ensure future success, I authored a best practices handbook outlining the testing methods, modeling techniques, and certification process. This handbook became a valuable resource for subsequent teams and was successfully adopted in following years to certify new chassis designs.

To gain a better understanding of the parts I was simulating, and get my head up from the screen, I became heavily involved in the hand layup of the composite chassis and components. This gave me a great appreciation for the practical elements of design to manufacture high quality composites.

This project combined hands-on, fabrication, mechanical testing, advanced simulation, and process development to push the boundaries of what our team could achieve to create safe, lightweight and winning race cars.